Create VDA label 4902 in SAP

The packaging data are sent by EDI in a precisely defined structure to the automobile manufacturer. As a rule, the automobile manufacturer already provides the packing instructions. If the materials are then packaged physically, the labels are also printed. Important is that the data on the label are identical to the corresponding EDI data. When e.g. in the EDI data the unit has been transferred as package type 006280, the printer can not print 6280 on the label. That is, blanks and leading zeros in the EDI data are also to be printed on the label or coded in the barcode.

The labels are only printed for genuine packaging materials such as KLT (small load boxes), GLT and pallets. For other packaging materials such as inserts and lids, no messages are generated and no labels are printed.

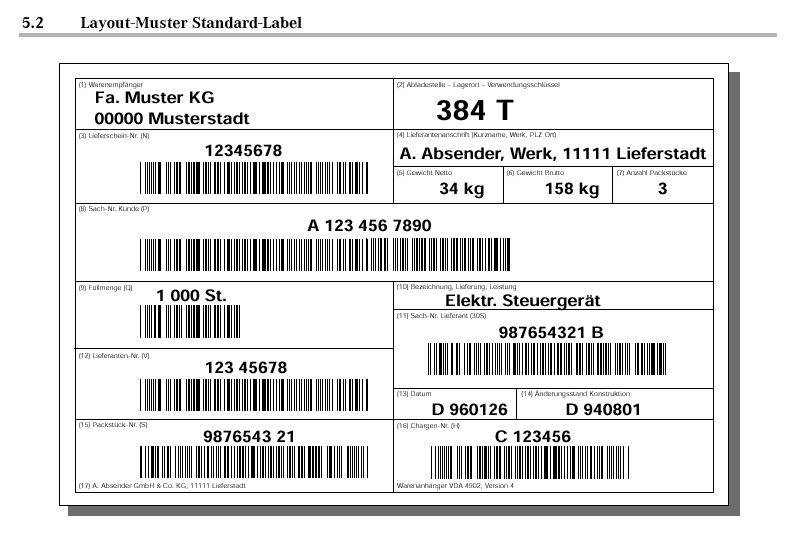

Layout of VDA label 4902

There are basically two different labels:

a) Standard label

The standard label has the format DIN A5 and is attached to GLTs and pallets with the help of adhesive dots.

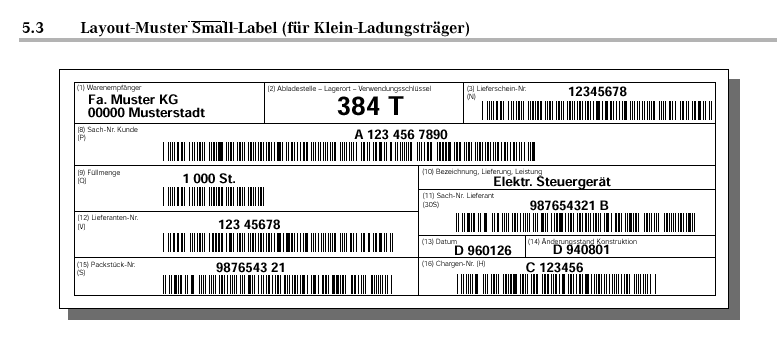

b) KLT label for small load boxes

The KLT label has the format half A5, is best printed on the center perforated DIN A5 card, then kinked and inserted into the KLT (small load box) into the slots provided for it.

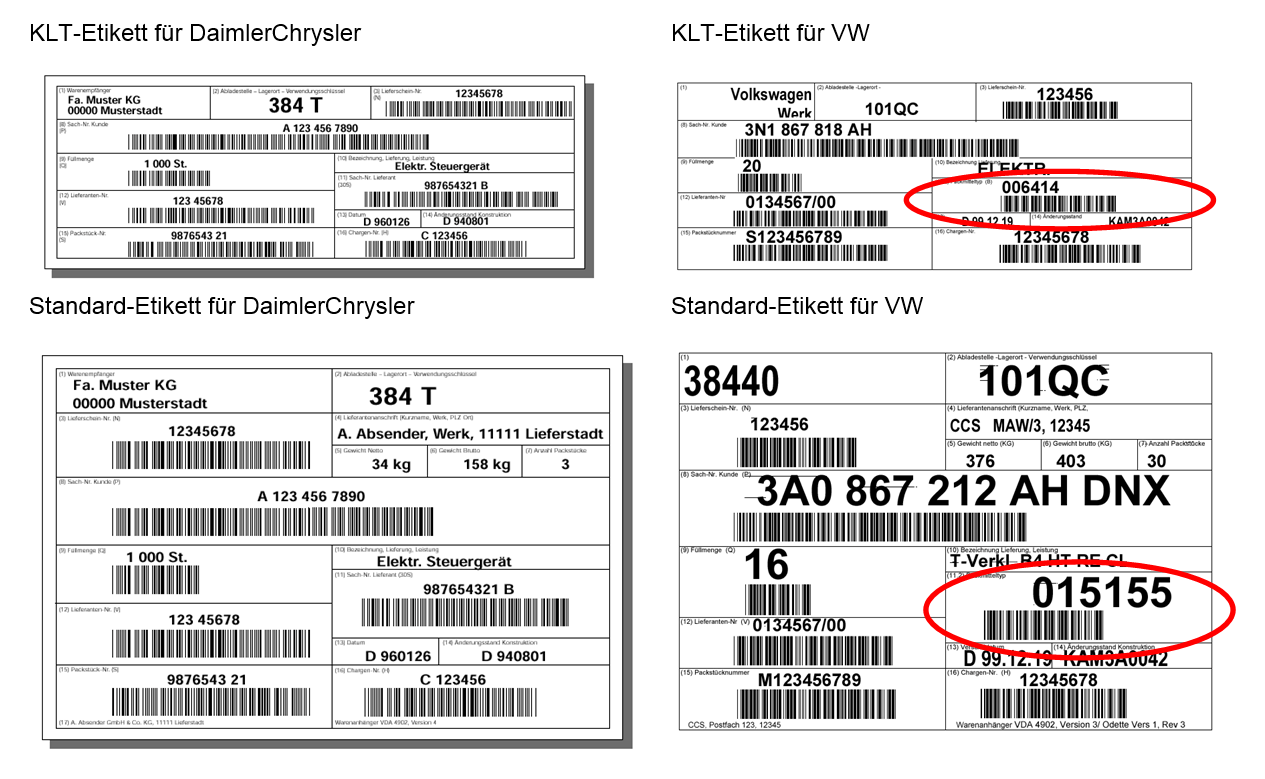

Differences in layout between automotive manufacturers

In principle, the VDA label 4902 are the same for all automotive manufacturers. Nevertheless, there are differences in the individual case. For example, in the field where VW places the packaging type, the vendor number is printed at Mercedes Benz.

Data on VDA label 4902

Basically, the data is printed as it appears in the EDI data. If data is coded in the barcode, the field is preceded by a leading letter, so that it is immediately possible to scan the field which has just been scanned, whether the delivery note, package number, etc.

| Feld | Datenherkunft | Bemerkungen |

| Consignee | Ship-to address | Factory of the car manufacturer according to the delivery request |

| Unloading point | Unloading point in delivery head, view transport | |

| Delivery note | Delivery number | Barcode starts with a leading N |

| Ship-to address | Shipping point name | |

| Weight net | Net weight HU | |

| Weight gross | Gross weight HU | |

| No. of packages | S – The number of packs with the same part number

M – for packs with the same part numbers in subpackages -> the number of packs with the same part number, G – in the case of packagings with different product numbers in subpackages -> the number of packages per main packaging (basic load carrier). |

|

| Customer materialCustomer material | Barcode starts with a leading P, if several materials are packed in the HU, the message MIX is sent, the barcode is not printed in this case | |

| Quantity | HU quantity | Barcode starts with a leading Q

S – for packs without subpackages -> quantity per item number in the package M – for packets with the same number in subpackages -> fill quantity = 0 in barcode -> fill quantity is not printed as plain text G – for packets with different product numbers in subpackages -> fill quantity = 0 in barcodefill quantity is not printed as plain text |

| Vendor number | Own vendor number, from master data sales-to party | Barcode starts with a leading V |

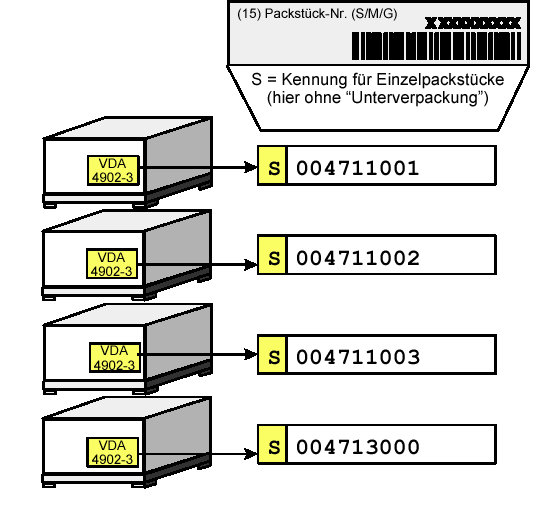

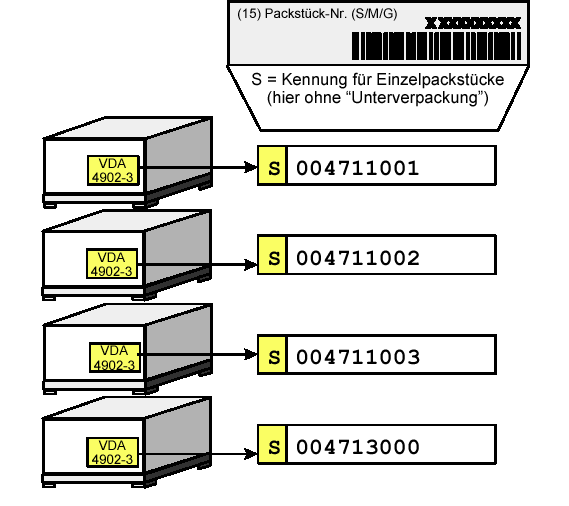

| Package number | external HU no. VEKP-EXIDV | S barcode starts with a leading S if all the materials in the package are the same

G – barcode starts with a leading G if |

| Description | Material description of delivery item | If it is a mixed delivery, the description is not printed, |

| Package type | Package type of customer (in HU head) | Barcode starts with a leading B |

| Date | Goods issue date | |

| Change construction | VWAHN-AESKD | |

| Batch number | Batch of delivery item | Barcode starts with a leading line item. In this field is expected if our technical delivery conditions for the delivered goods demand this entry. Otherwise, the field should not be filled. |

Barcode printing

All bar codes are the Code 39 barcode types.

Cases

Case 1: Delivery items of the same part number are packaged in KLTs

All items of a delivery with the same part number are packaged in KLTs. That is, In each KLT there is only one material. A KLT label is printed.

| Part number customer | is printed |

| Quantity | Number of items in KLT |

| Delivery description | is printed |

| Package number | starts with a S |

Case 2: Delivery items with different part numbers are not packaged in KLTs

There are at least 2 materials in a KLT. A KLT label is printed.

| Part number customer | in plain text, MIXES DELIVERY is printed, barcode is not printed at all |

| Quantity | is not printed at all, Barcode not printed |

| Delivery description | is not printed at all |

| Package number | starts with a G |

All items of a delivery with the same part number are packaged in GLTs. That is, In each GLT there is only one material. A standard label is printed.

| Part number customer | is printed |

| Quantity | Number of positions in GLT |

| Delivery description | is printed |

| Package number | starts with a S |

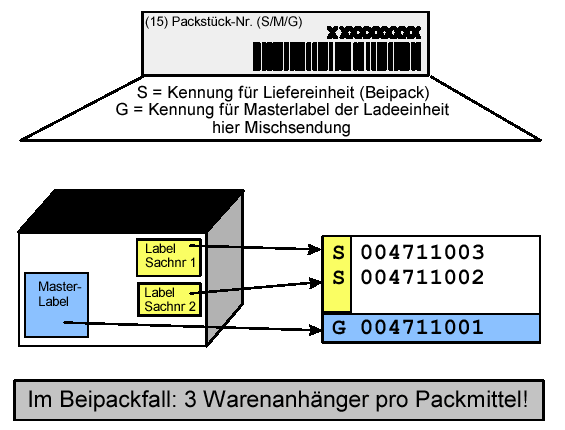

There are at least 2 materials in a GLT. In this case, multiple labels must be printed, a master label, and multiple child labels. When e.g. In a GLT 2 materials are packaged, a master label and 2 child labels are printed. The same package number is printed on the master and child label.

Data on the master label

| Part number customer | in plain text, MIXES DELIVERY is printed, barcode is not printed at all |

| Quantity | is not printed at all, Barcode not printed |

| Delivery description | is not printed at all |

| Package number | starts with a G |

Data an the child label

| Part number customer | is printed |

| Quantity | Material qty. in HU |

| Delivery description | is printed |

| Package number | starts with a S |

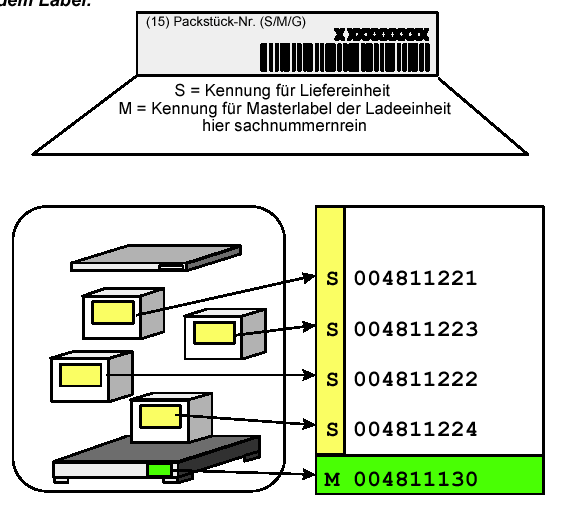

Case 5: A delivery item with the same part number is packaged in several KLTs which in turn are on a pallet

A delivery with a delivery position has been described in e.g. 4 KLTs, which in turn are placed on a pallet. On the pallet, there is therefore a product-number-free shipment. In this case, a standard label with label S is printed for each KLT and a standard label for the pallet with packing ID M.

Data on KLT label

|

is printed | |

| Quantity | Material qty. in HU | |

| Delivery description | is printed | |

| Package number | starts with a S |

Data on the pallet label

| Part number customer | is printed | |

| Quantity | Material qty. in HU | |

| Delivery description |

|

| Package number | starts with a S |

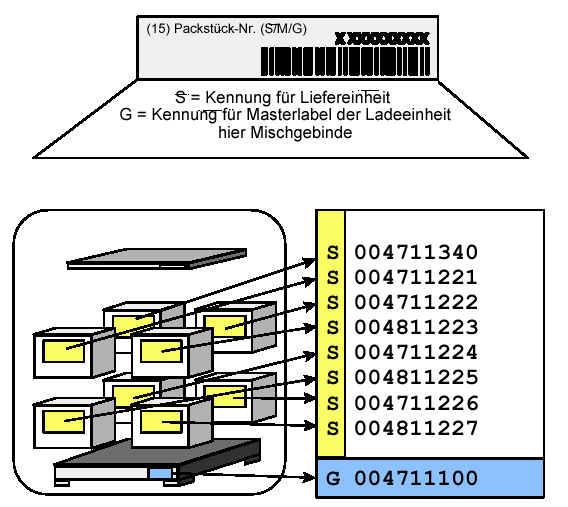

Case 6: Multiple delivery items are packaged in several KLTs, which in turn are on a pallet

A multi-item delivery is item numbered in e.g. 4 KLTs, which in turn are placed on a pallet. On the pallet there is therefore a consignment, which is per person per KLT, but is not relevant for the pallet. In this case, a standard label with label S is printed for each KLT and a standard label for the pallet with package ID G.

Data on KLT label

| Part number customer | is printed | |

| Quantity | is printed | |

| Delivery description | is printed | |

| Package number |

|

Data on the pallet label

| Part number customer | in plain text, MIXES DELIVERY is printed, barcode is not printed at all | |

| Quantity |

|

|

| Delivery description | is not printed at all | |

| Package number |

|

Case 7: Several delivery items are not packaged into several KLTs which in turn are on a pallet

A multi-position delivery is provided in e.g. 4 KLTs, which in turn are placed on a pallet. A KLT is factual, the other 3 KLTs are not numbered. On the pallet there is therefore a consignment, which is not relevant for each KLT as well as for the pallet is not numbered. In this case, a standard label with a pack label S is printed for a KLT, a standard label with a pack label G for the remaining KLTs, and a standard label with a pack label G for the pallet.

Data on the KLT label with the same part numbers

| Part number customer | is printed | |

| Quantity | is printed | |

| Delivery description | is printed | |

| Package number |

|

Data on the KLT labels with fifferent part numbers

| Part number customer | in plain text, MIXES DELIVERY is printed, barcode is not printed at all | |

| Quantity |

|

|

| Bezeichnung Lieferung | is not printed at all | |

| Package number |

|

Data on the pallet label

| Part number customer | in plain text, MIXES DELIVERY is printed, barcode is not printed at all | |

| Füllmenge |

|

|

| Bezeichnung Lieferung | is not printed at all | |

| Package number | beginnt mit einem G |

First printout

Printing is triggered manually in TRX VL74 by entering a delivery.

Repeat printout

The repeat printout is possible from transaction VL74 or delivery -> packaging / loading -> VSE messages. A delivery number is entered on the selection screen and entered as processing mode =, 2 ‘. Then the individual shipping elements of the selected delivery will appear. By marking a shipping element, the goods hanger can be printed again.