Business scenario

A manufacturer and distributor of medical products produces and distributes materials for hospitals. The products are subject to strict compliance criteria and must be clearly labeled.

The following information can be found on the product labels:

- Material number

- Material description in several languages

- Batch number

- Production d

- Expiration date

The product label also contains various pictograms to indicate its use and storage.

Initial situation

SSeveral employees in the production order preparation were busy producing the product labels. They used a label program where they opened a template for each production order and still maintained

- Material number

- Batch number

- Production date

- Expiration date

in dialog boxes of the label program. When the production order was released, the product labels were also printed in the expected quantity and the production order paper was added.

This process had the following consequences:

- The process was very unproductive. Several employees were busy with the label print.

- There was a considerable number of misprints due to false information and the label printing had to be initiated once again.

- Often too many labels were printed.

- Labels were lost on the way to the labeling of the goods.

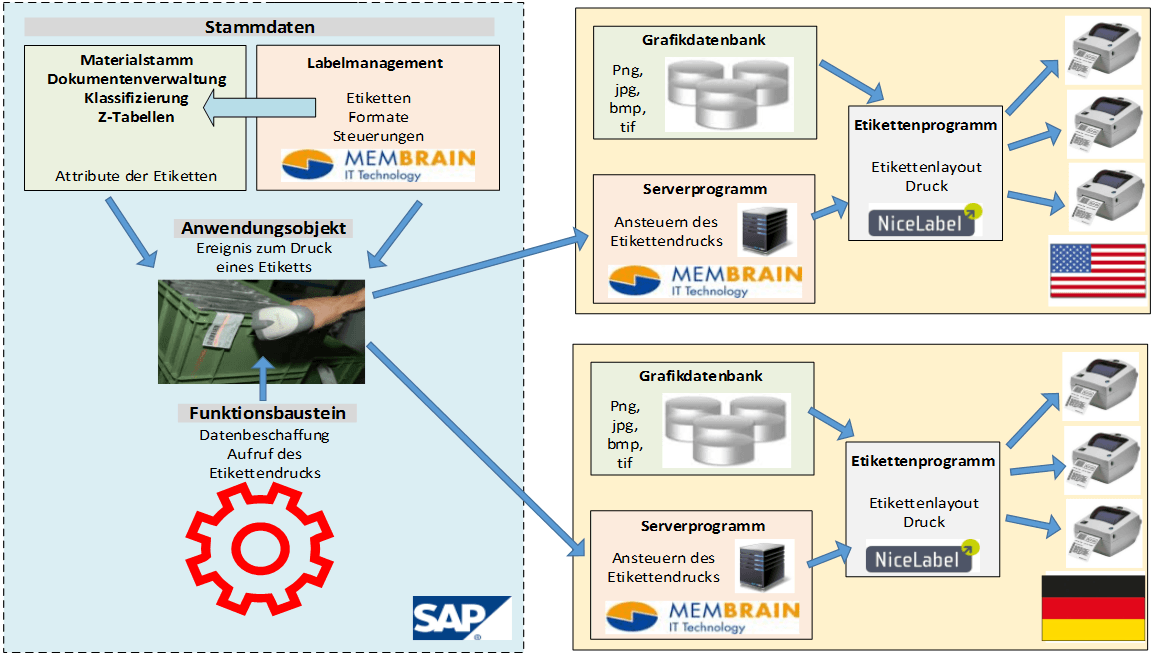

Schematic illustration of an SAP Label management with membrain

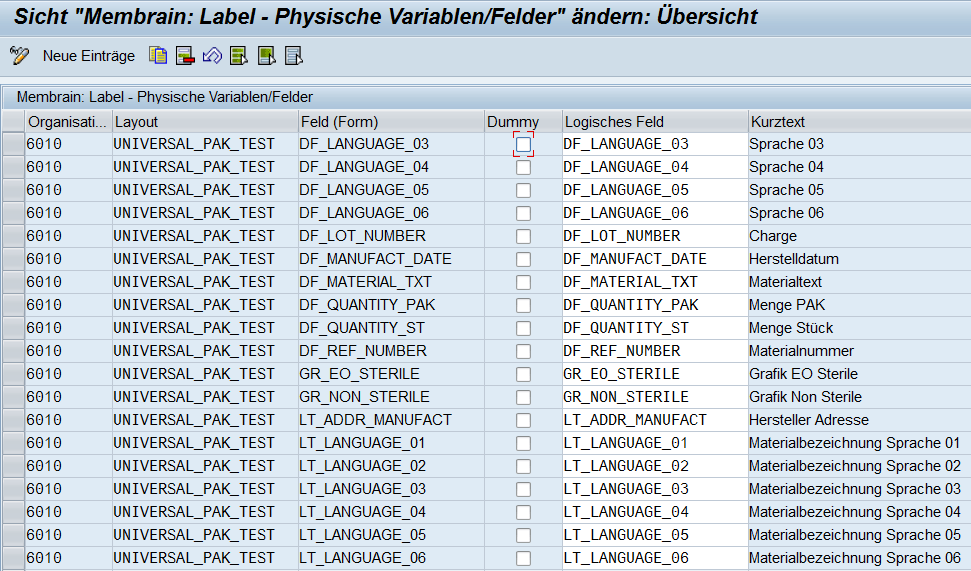

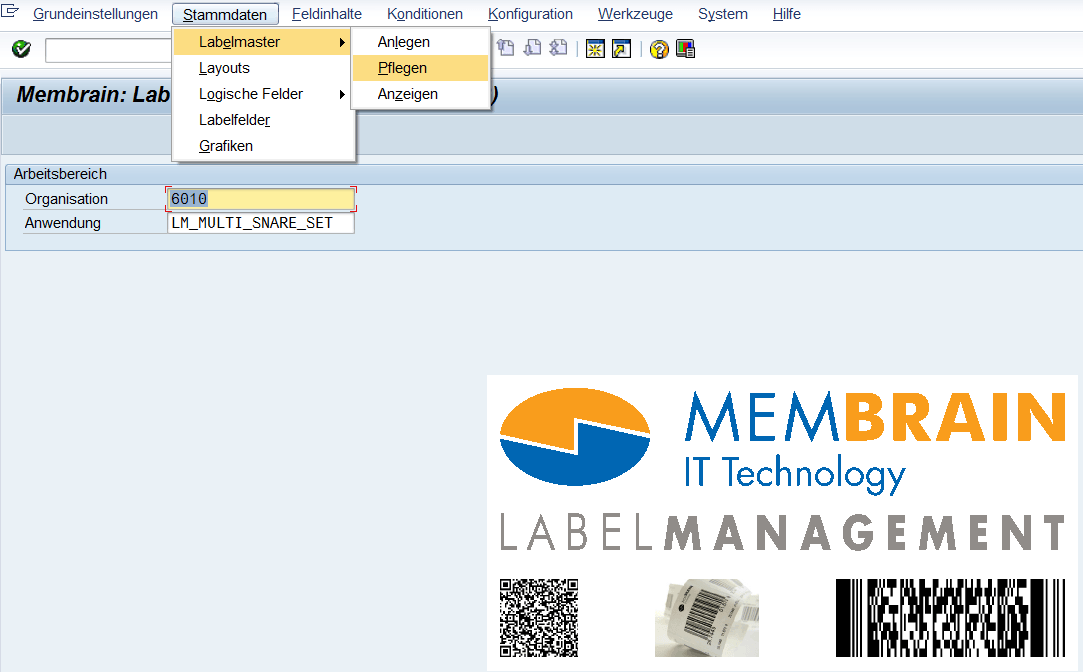

- Maintenance of label data with variables in membrain label management

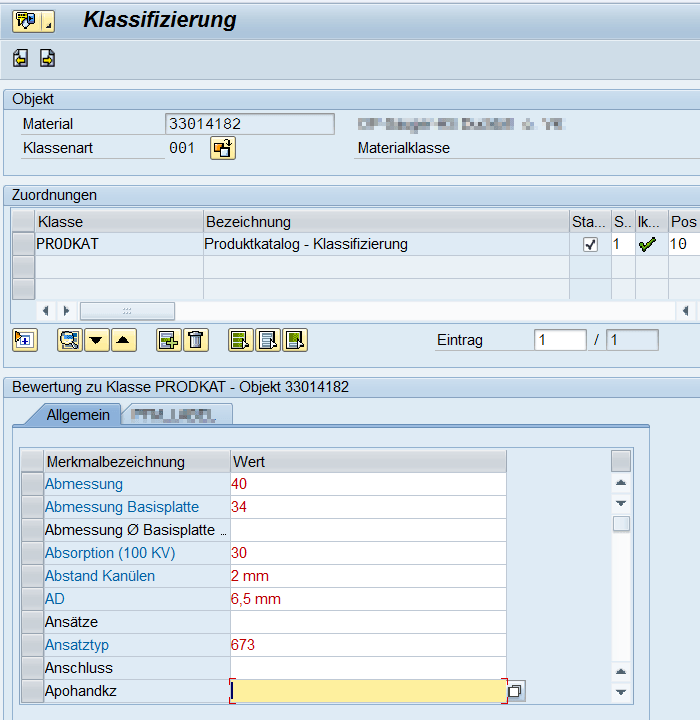

- Storing label data in SAP application objects, such as the material master with classification

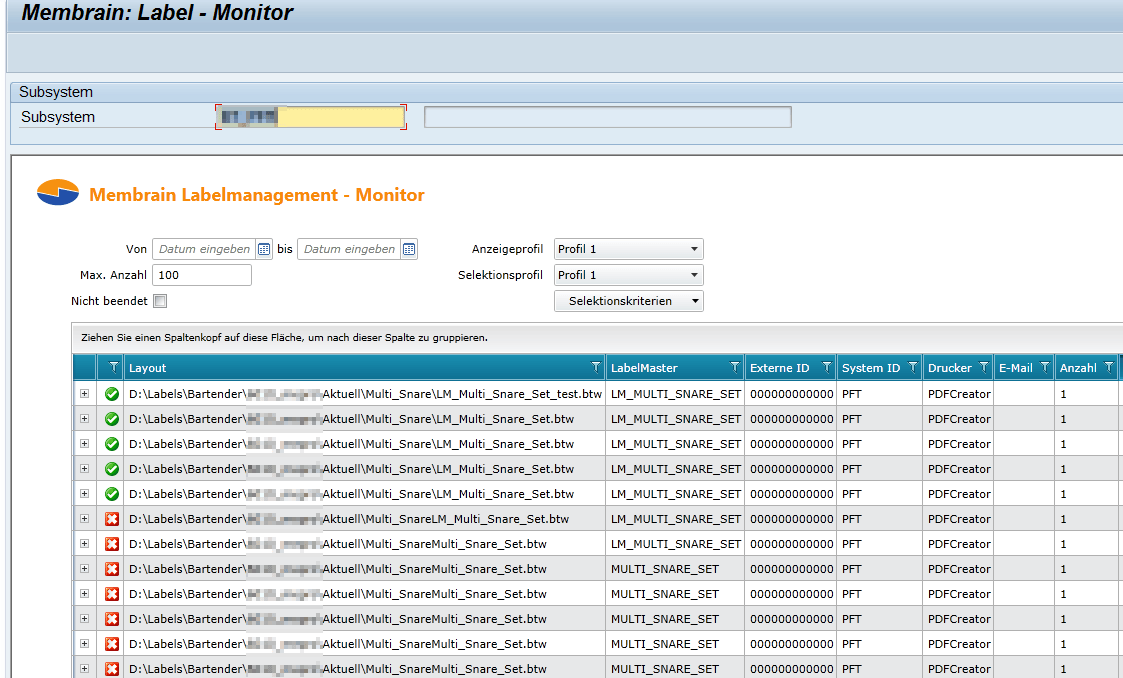

- At the time of printing, the system determines the correct label, fetches the master data to the label with variables from the label manager, calls the function module for data selection, which fills the variables of the label with the data at runtime.

- By means of an RFC call, the label data are transferred to the RFC server using meta data (printer, label, ..).

- The RFC server controls the label printing via the software Bartender or Nicelabel.

- Bartender or Nicelabel renders the label form and passes it to the printer.

New business process with direct label printing from SAP

After a careful analysis of the label variability, the information was structured label by label. The content of each label was checked where the information came from or whether the element could be firmly anchored in the label. Data sources can be:

- Material master

- Membrain Label management

- Graphic files with path details

- Long texts

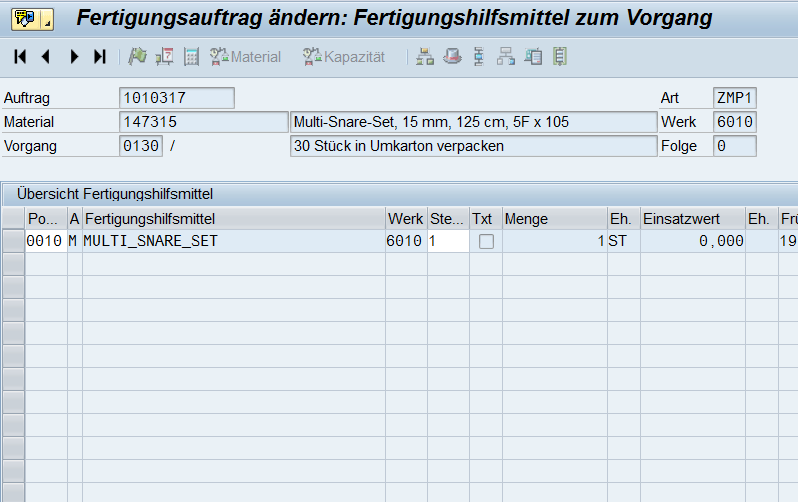

- Data fields from the SAP application object (batch, production order, …)

Das Design des Prozesses erfolgte mit dem Ziel, das fertige Etikett zum Zeitpunkt der Rückmeldung eines Arbeitsvorgangs zum Fertigungsauftrag aus dem Programm Bartender zu drucken. Hierfür wurden folgende Bausteine gebildet:

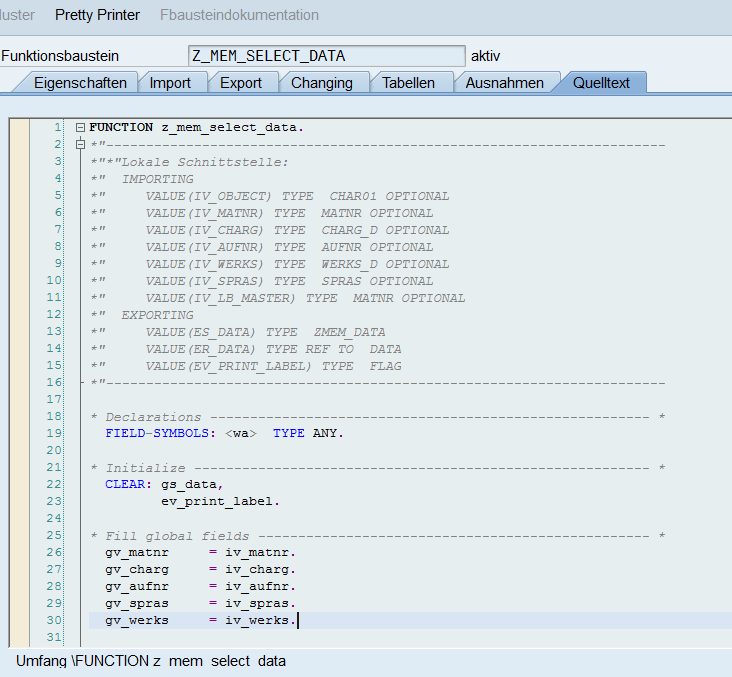

The aim of the process design wasto print the finished label from the Bartender program at the time of the confirmation of a sequence for the production order. For this purpose, the following modules were formed:

Results

The project objectives were achieved in all aspects. Here are the results in detail:

- Former, two employees spent 3/4 of the day with label design and label printing for production orders. Now, the employee only needs to design a new label from time to time.

- The quality of the label data has improved. Complex re-labeling due to incorrect data on the label has been greatly reduced.

For further Informationen go to membrain Homepage,