Business scenario

A furniture manufacturer produces shelves and sells them

a) under his own name or

b) under the respective trade mark of the dealer.

During the manufacturing process, cartons with the shelves are labeled at the packaging machine.

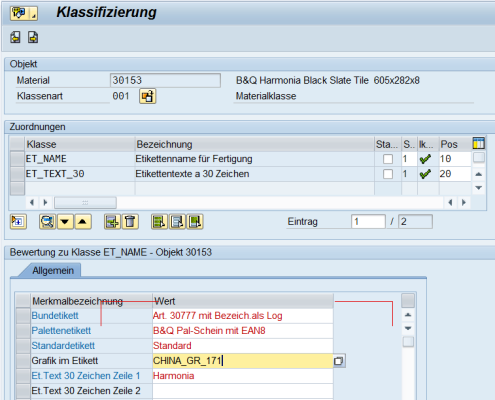

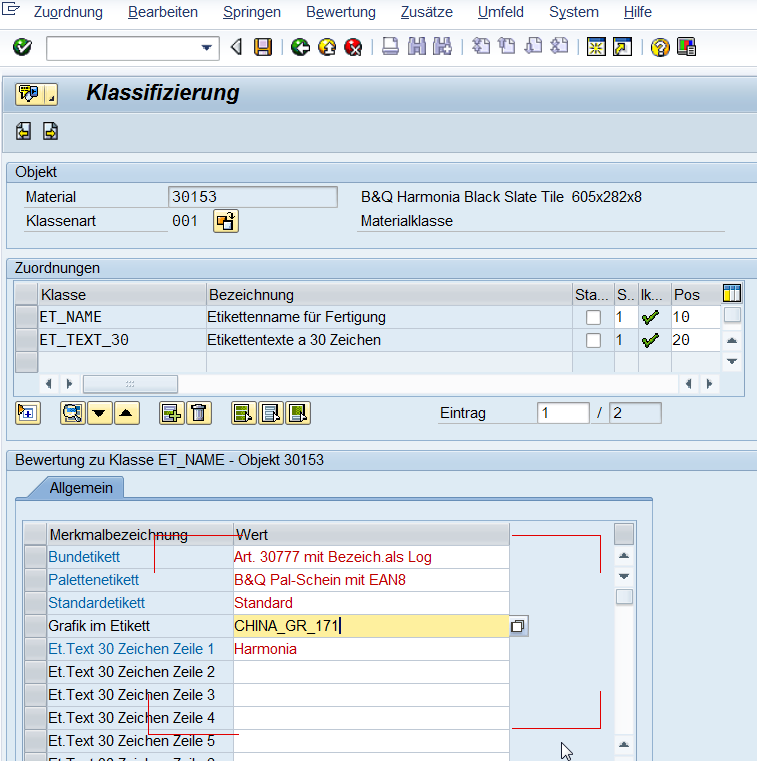

Since the labels can contain customer-specific data, e.g. a logo or the sales price, there is a great variability in the layout of the labels.

Initial situation

A production order for a shelf system is exactly assigned to one customer. Before the production order was placed in production, an employee created a label with a graphic layout manager. The label contains the following information:

- Manufacturing order number

- Customer logo

- Retail price

- EAN number (GTIN) of the customer

- Customer material number

The employee has placed the label as a file on the computer of the printing unit on the packaging machine.

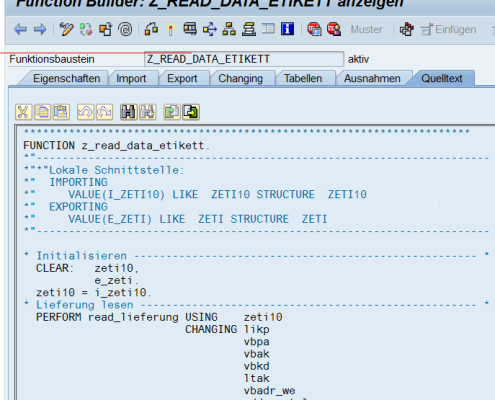

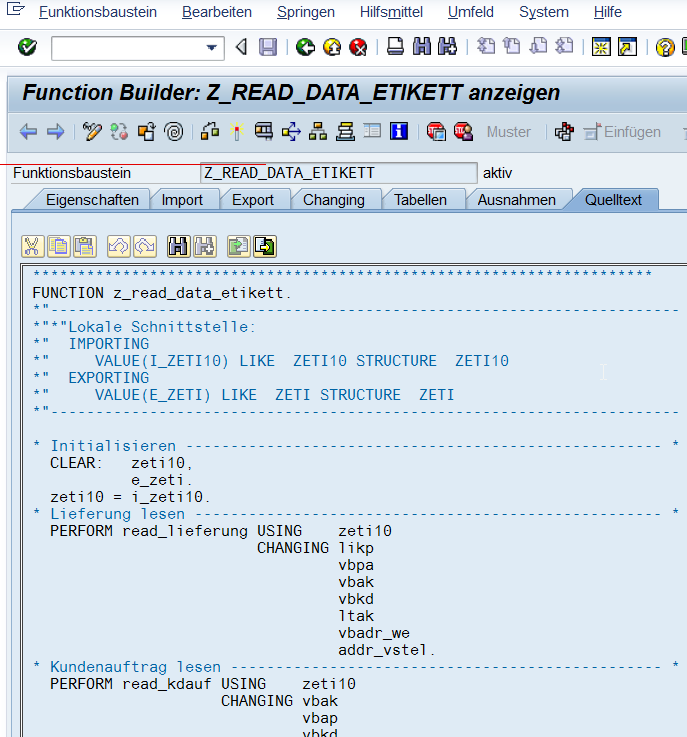

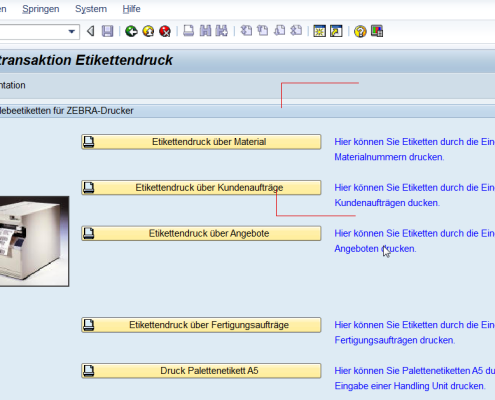

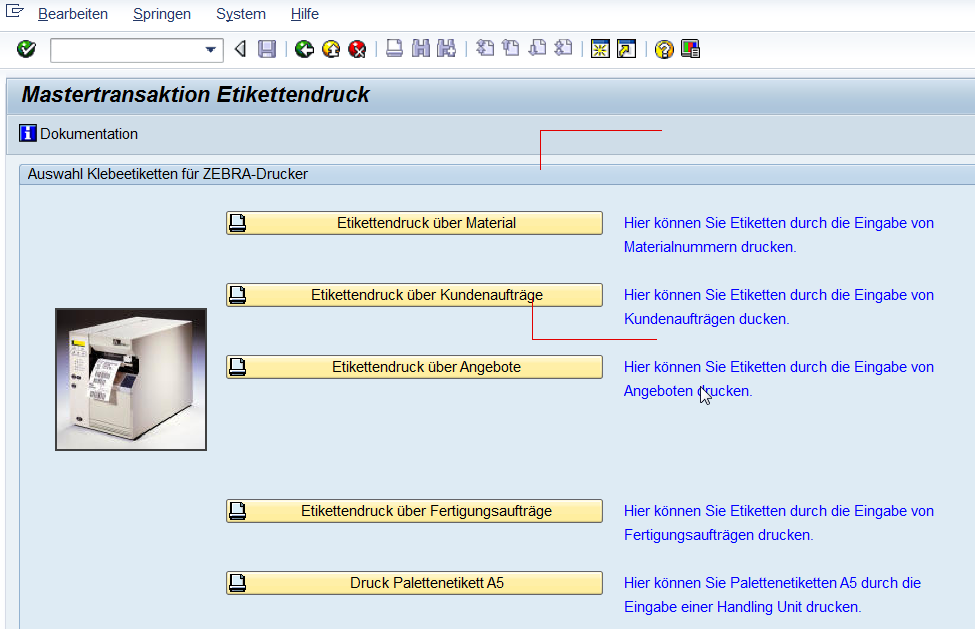

New business process with direct label printing from SAP

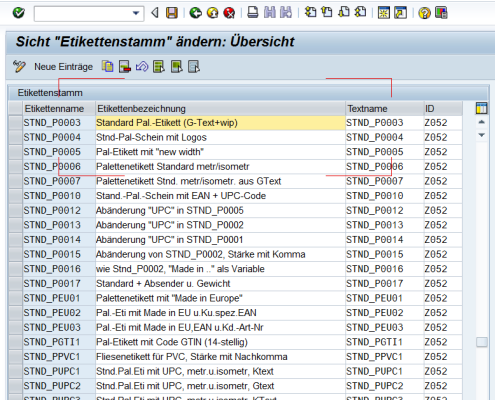

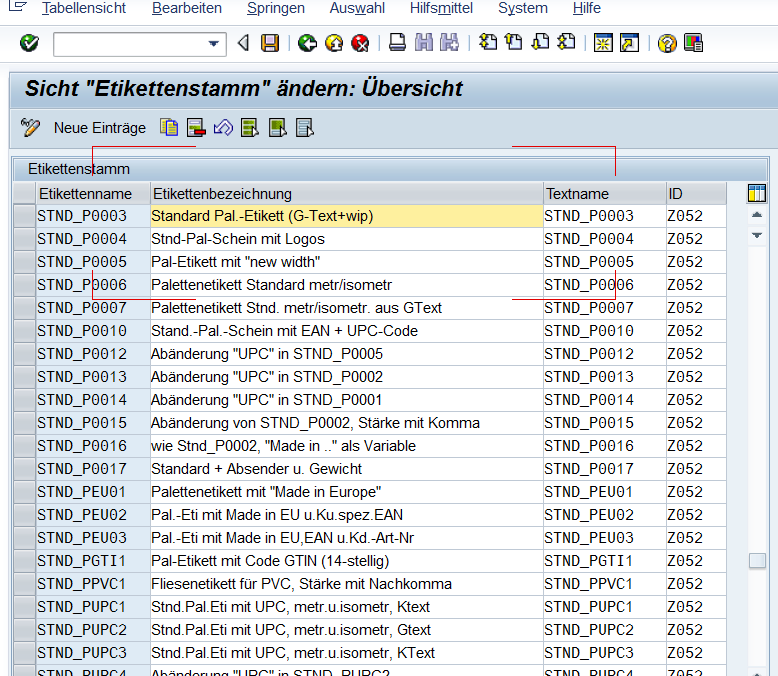

After a careful analysis of the variability of the labels, building blocks were formed, which were then combined according to a certain set of rules to generate the label layout. The finished label is sent as print file to the printer harddisk at the packaging machine when the production order is released.

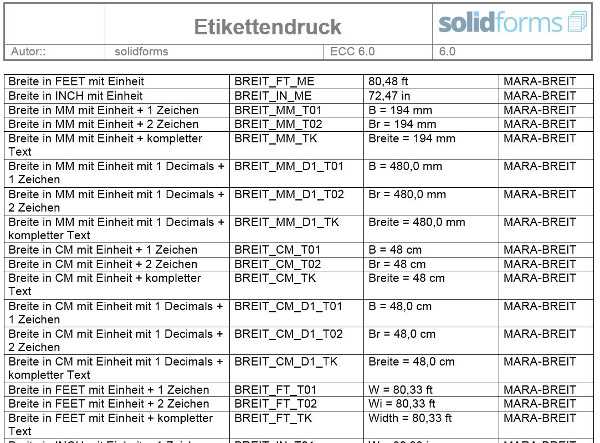

The following modules were created:

Results

The project objectives were achieved in all aspects. The following results were obtained in detail:

- Former, an employee was busy the whole day to create labels for the production orders. Now, the employee only needs to create a new label to implement a new label layout.

- The label data quality has improved. Complex re-labeling due to incorrect data on the label has been greatly reduced.